Topic of your interest

The printing systems are thoroughly tested and certified on the basis of the extensive criteria of ISO 12647-8. The certification comes with a certificate and a FograCert logo in addition to the technical test report, which shows the product's conformity to ISO 12647-8. Certification details are listed in our FograCert database.

Our procedure

Preparation phase:

Agreement on the system combinations

Delivery of the digital test forms

Test phase:

approx. two-day audit on site, carried out by a Fogra employee

Evaluation of the results in the Fogra laboratory

In case of a successful certification we issue a certificate and list your system in our FograCert database.

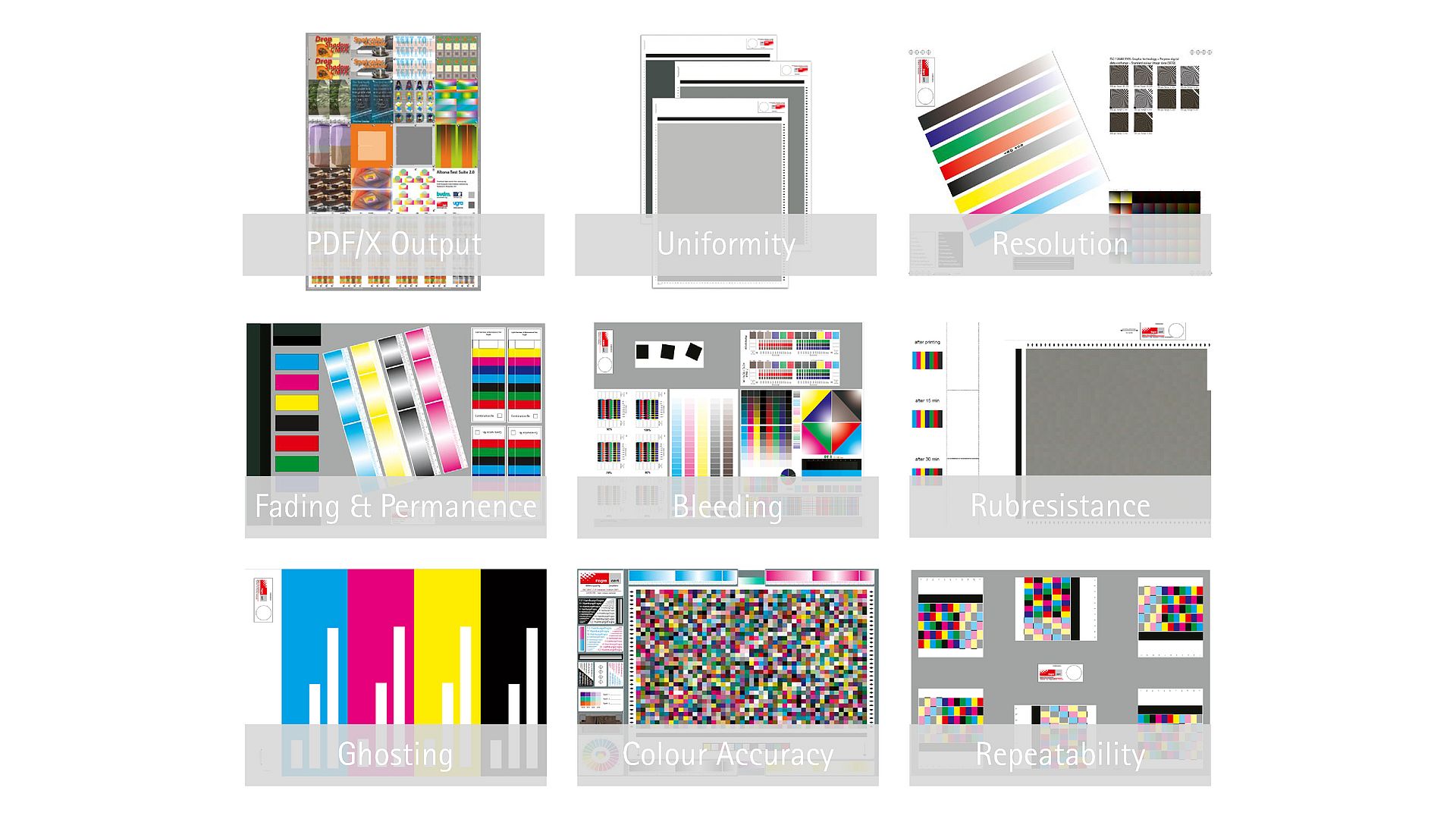

Your printing system is examined against the following criteria:

PDF/X compliance: Ghent Output Suite 5.0 and informative evaluation of Altona Test Suite 2.0 Technical 2

Gloss, coloration and fluorescence of the substrate

Colour accuracy incl. colour gamut

Uniformity

Aging and light fastness

Colour drift (fading)

Short- and long-term repeatability

Mechanical stability (drying)

Colorimetric tonal value transfer

Tone value reproduction limits/ gradients

Image register and resolving power

Margin information

Remote certification

We also offer the VPS certification with online procedure while maintaining the quality standards and support you securely and flexibly through the entire certification process:

Setup of the communication platform

Process planning and creation of the test regime on individual basis

Live support during the test

Analysis of intermediate results in real time

Final evaluation of the sent print copies in the Fogra laboratory

The reference printing conditions? Unlimited!

The reference printing conditions are freely selectable by you!

For example, if you have a wide-gamut printing system and would like to prove its potential with VPS certification, the reference FOGRA53 (eciCMYK) is conceivable. An overview of all common reference printing conditions can be found here:

When are two systems similar or comparable?

The question often arises as to when two systems are similar or comparable. The background to this is to avoid duplicate tests. In principle, two presses or combinations are the same if the changes have no negative effect on the resulting colour quality. Since this is formally very difficult to handle, the following questions should help to answer the question. It is important to note that this is always a case-by-case decision.

If the following questions can be answered with Yes, the systems are considered to be the same as such could be included in the list of certified printing systems and marked accordingly:

Are the same consumables being used?

Is the same substrate transport used?

Is the same imaging unit used?

Is the same drying or fixing mechanism used?

Is the production speed less than or equal to the press already tested?