Topic of your interest

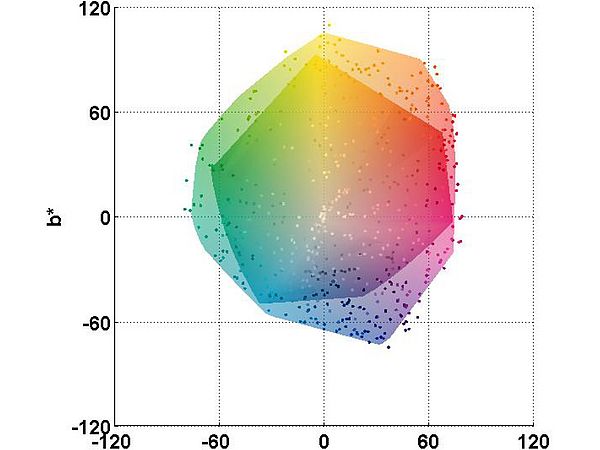

Visual and metrological characterization of metallic effects to increase process reliability in packaging printing

Prepress technology 05/31/2024

The aim is to clarify which properties in human perception are responsible for the expression of the metallic effect.

Printing standard for seven-colour offset packaging printing

Offset printing 11/30/2023

The aim is to characterise OGV printing inks, folding boxboard and label papers on the market using laboratory techniques.

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/7/1/csm_fogra-heatset_8f991b0f76.jpg)

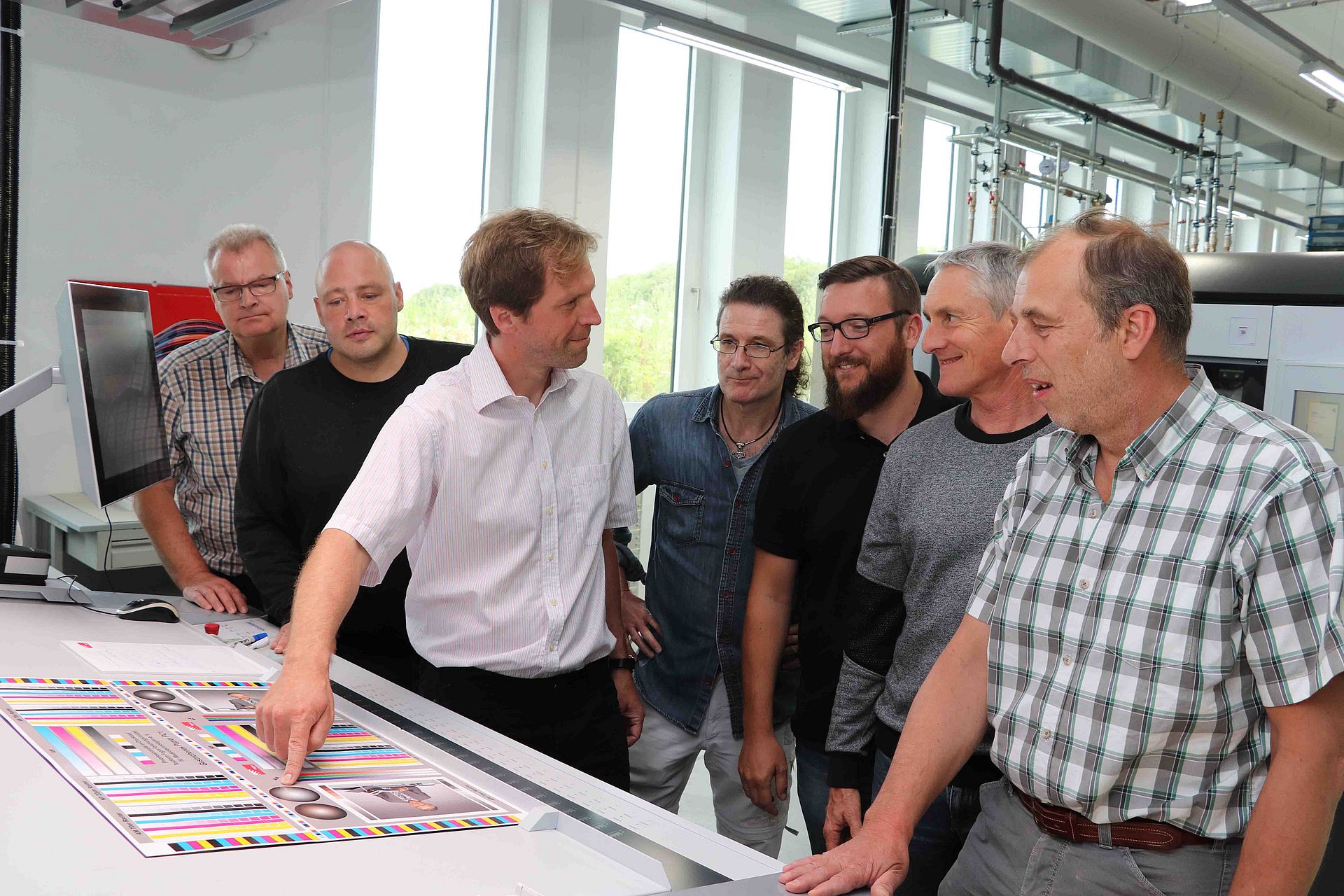

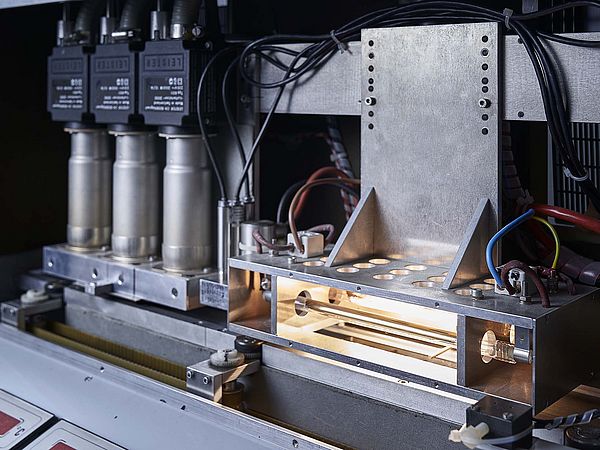

Increased economic efficiency and sustainability of print production with heatset offset presses through independence from natural gas

Offset printing 01/01/2023

The research project is intended to help make print production with heatset offset presses more economical and sustainable.

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/4/3/csm_fogra-papierstapel_ca2398c293.jpg)

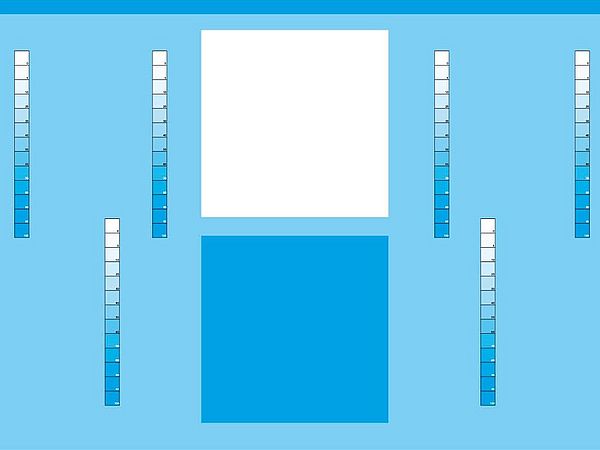

Mackle and CO2 savings through paper-dependent pre-adjustment of sheet-fed offset presses

Offset printing 08/31/2022

The aim is to establish a new paper characteristic value that allows to predict the expected solid tone densities and tone value increases.

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/0/d/csm_Fogra_ISO_Score_Frontpage_caa1cd1438.png)

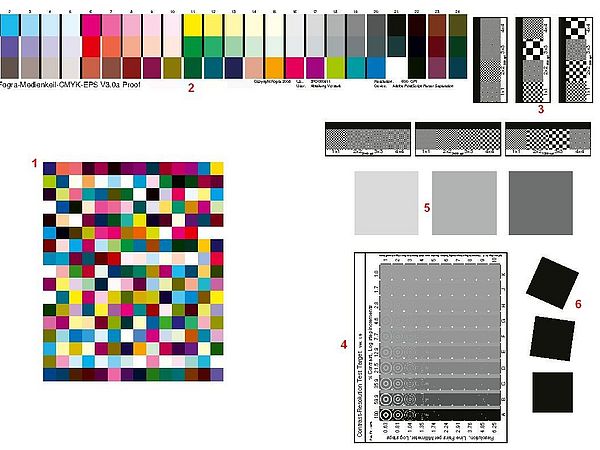

ISO-Score

Prepress technology 08/24/2022

The aim of this project is to develop a cross-process print quality assessment procedure (ISO score)

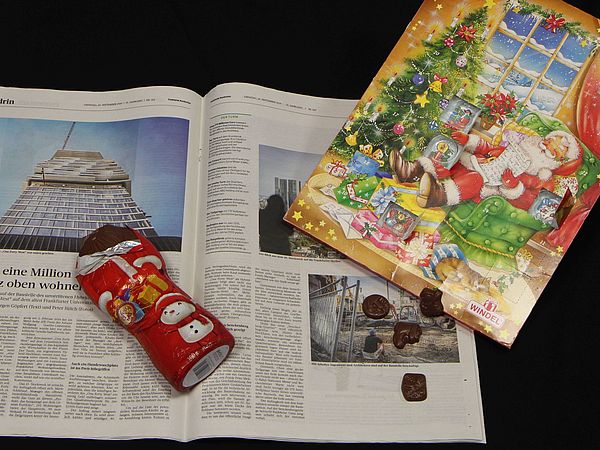

Material compatibility and deinking of mineral oil free Coldset inks

Offset printing 03/01/2021

The aim is to improve the deinkability of mineral oil-free newspaper inks and to establish a new reference set for the swelling behavior.

Communication of characteristic values describing the metallic appearance of prints

Offset printing 10/31/2020

Objective parameters are to be established that correlate with the visual impression of printed metal surfaces.

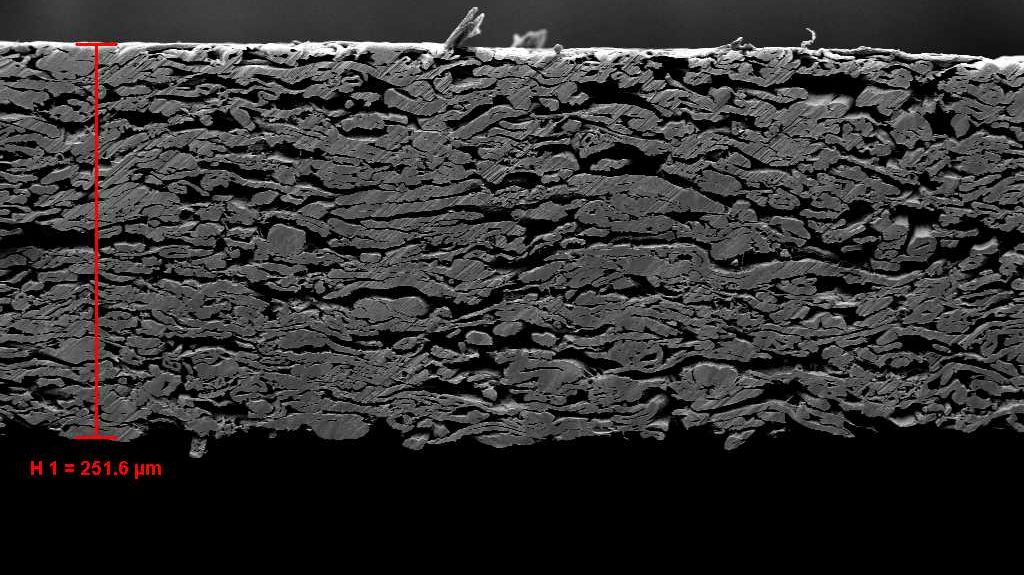

Laboratory method for the practical and reproducible determination of the residual strength of papers for heatset web offset printing

Offset printing 03/31/2020

Within the scope of the research project, an already existing laboratory method for testing the residual strength is to be further developed.

Integration of the highspeed inkjet into conventional offset production environments

Offset printing 10/31/2019

Typical offset print products are to be identified and provided with quality requirements that are customary in practice.

Modelling the printing behaviour in sheet-fed offset printing on the basis of measurable paper properties

Offset printing 04/30/2018

The paper-side factors influencing solid tone colouring and tone value increases in sheet-fed offset are to be determined.

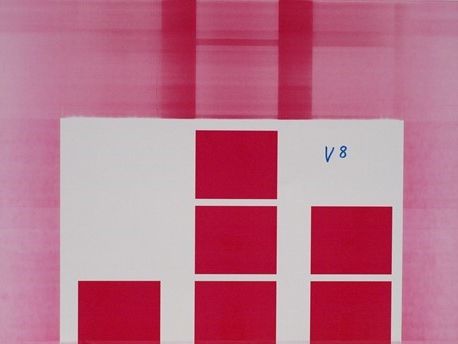

Reduction of "Picture Framing" in sheet-fed offset printing through targeted selection of material and application parameters

Offset printing 03/31/2018

Within the framework of the research project, a better understanding of the development mechanisms of "Picture Framing" is to be achieved.

Our clients are print shops and print buyers as well as manufacturers of printing machines, inks and papers.

A typical concern is the assessment and troubleshooting of complaints regarding print quality or the used materials. However, there is also a frequent demand for investigations that are intended to serve the further development of products.

The ProcessStandard Offset (PSO) and the ISO 12647 series of standards are considered to be indispensable tools for colour reliable print production. The use of printing inks in accordance with ISO 2846 is a prerequisite for achieving the target values specified therein. Fogra also certifies the consumables and additives required for the printing process, e.g. fountain concentrates and washing agents.

PSO (ISO 12647)

With the certification according to PSO (ISO 12647), printing companies ensure a smooth printing process internally. Externally, they demonstrate their ability to produce in accordance with the high quality requirements of the internationally recognized standard and to comply with the colour specifications of their customers.

PSOactive

PSOactive is a supplement to the certification according to PSO (ISO 12647) and is offered to certified print shops as an additional option. In order to guarantee consistently standardized print production even between the test dates, prints must be sent in regularly for metrological testing.

PSObasic

In order to expand the international circle of certified print shops, Fogra outside of the German-speaking DACH region offers a cost-effective variant called PSObasic. This is based on the same target values and tolerances as the certification according to PSO (ISO 12647), but follows a reduced scope of testing. PSObasic thus serves as a stepping stone to obtaining the more comprehensive PSO certificate.

![Fogra approval of washing agents [Translate to EN:] Fogra Waschmittelfreigabe](/fileadmin/_processed_/2/3/csm_fogra-washing-agent_8f4f025a62.jpg)