Topic of your interest

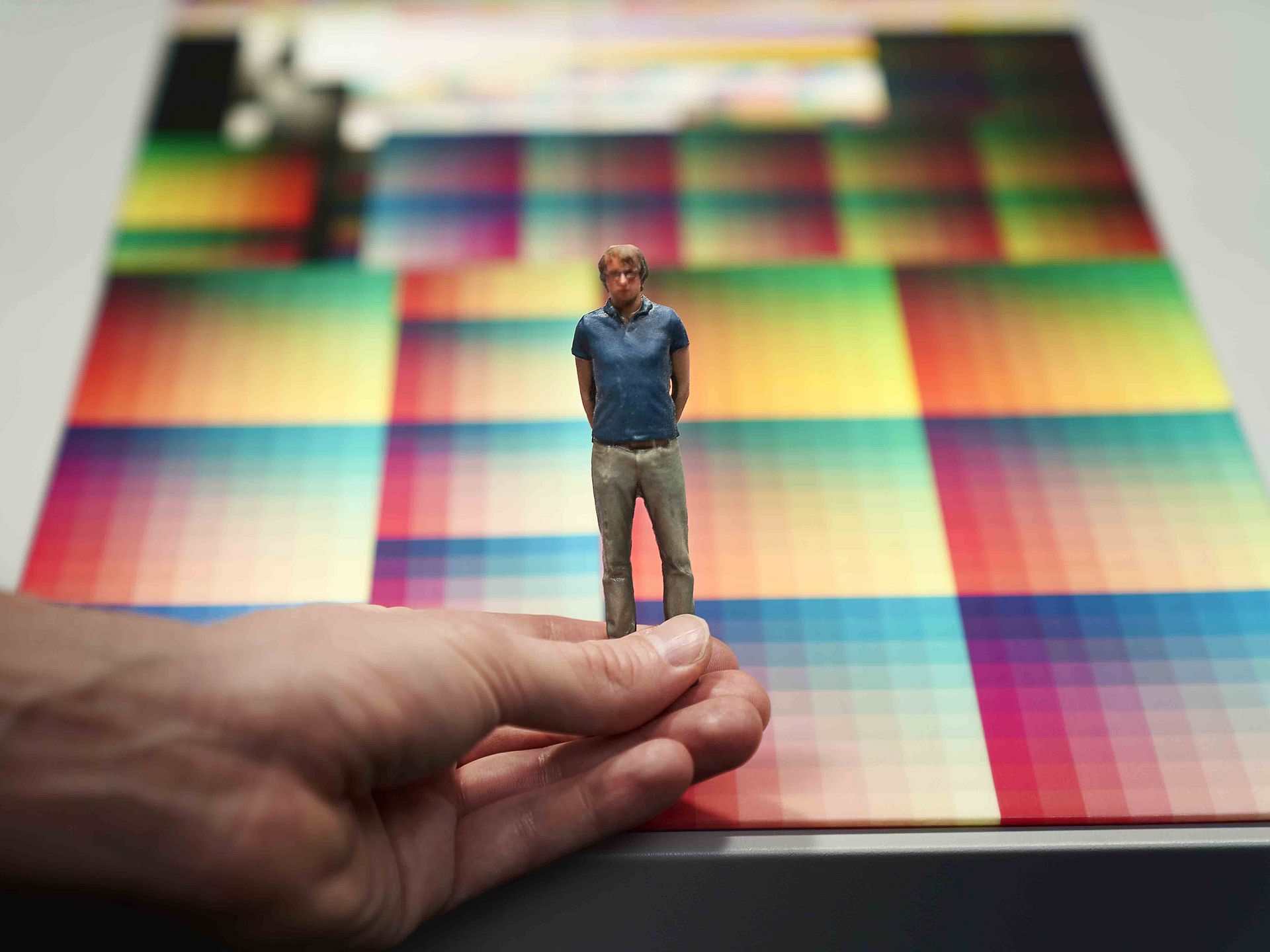

The aim of the project is to design a 3D softproof for full-colour 3D printers. It is expected that the Polyjet or Multijet Fusion technology will replace 3D powder printing (3DP) in graphic 3D printing. Therefore, these promising successors of the 3DP process are the subject of the research project.

Solution steps

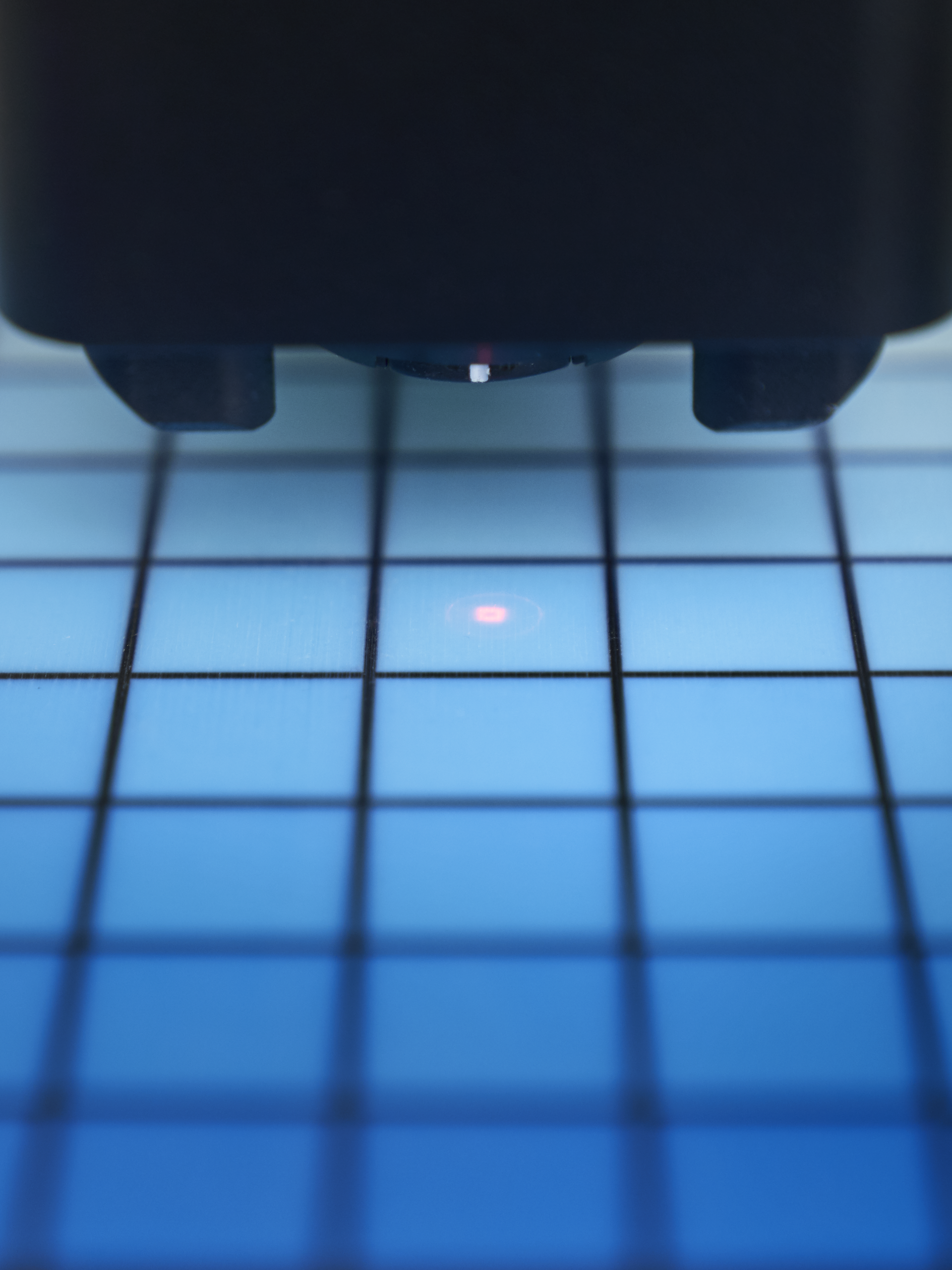

The first of 3 focal points deals with the characterisation of 3D printers. For quality assurance along the process chain in 3D printing, it is essential to record visually plausible measurement data that provide information about the colour fidelity of the printed products. There are no standardised measuring and sampling methods for 3D printing yet. To solve this dilemma, the main factors influencing the overall visual impression of the printed products are determined by test prints.

In the second focal point, a freely parameterisable

In the last focal point, the material data determined in the first focal point and the “rendering algorithm” developed in the second focal point are embedded in the iccMAX framework developed by the ICC.

In addition, the developed test panels will also be coded as 3MF and OBJ files in order to achieve the highest possible acceptance by SMEs.

results

Within the framework of this research project, the practical basics for the physically correct digital representation of objects created in 3D printing were investigated. To this end, a concept for a renderer was developed at the beginning that takes physical object parameters into account. It includes the characterization of the necessary 3D environment including all relevant objects. The necessary scene information includes the viewing conditions (environmental map), the optical properties of the printing materials used as well as information about the concrete printing settings used.

Based on this requirement description, one focus was dedicated to the characterisation of the scene environment (environment map), which was realised by means of high dynamic range (HDR), as well as the data-driven and model-based description of the angle-dependent reflection properties (BRDF). Specifically, full-colour 3D printers from Stratasys, Mimaki (both polyjet printing) and HP (multijet fusion process) were used.

Publications & intermediate findings

| Title | Version | Date | File type | Download |

|---|---|---|---|---|

| Final presentation at PA meeting on 2021-03-01 | 01.03.2021 | Download | ||

| Converting instrument readings into visual plausible colour | 05.02.2021 | Download |