Topic of your interest

What you need to do

You put together print samples that have been cured under different conditions. Depending on the issue at hand (e.g. general energy savings, security in the printing process), different levels of curing can be achieved both via the lamp output and the printing speed. We will be happy to assist you in making the right choice of printing conditions.

For the tests we need

the print porducts to be tested,

approx. 100 ml of liquid, unprinted samples of each of the printing inks / varnishes to be tested,

ideally, samples of the substrate on which you will make the test prints in the printing press.

Please send your samples to:

Fogra Forschungsinstitut für Medientechnologien e.V.

Department Materials & Environment

Einsteinring 1a

85609 Aschheim b. München

Germany

Our procedure

After viewing all the materials, we will define the framework conditions with you and discuss the analysis tasks, test methods and work steps that we have to perform. After receipt of your order you will receive an order confirmation, in which all details regarding test period, contact person and price are summarised. Finally, we carry out the commissioned tests:

To determine the curing, proofs are produced on the test printing device in the Fogra laboratory with each ink or varnish to be tested. These are measured both uncured and after complete curing (scale for evaluating the real samples). As the measured values change depending on the ink or coating, calibration is necessary in each case. At Fogra, various lamp systems (differently doped mercury medium pressure lamps and LEDs of different wavelengths) are available for curing.

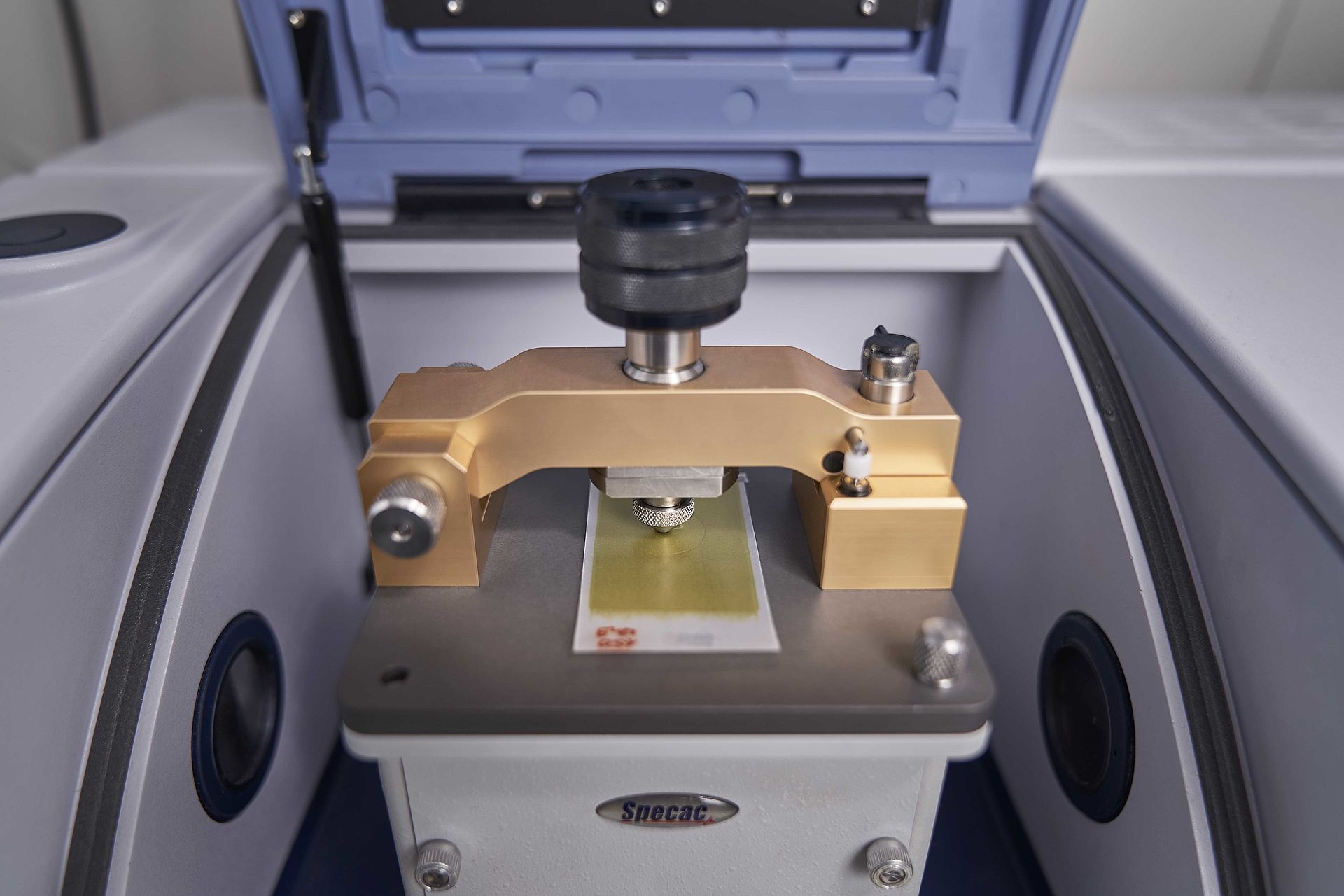

The measurement of the references and your print samples is carried out by means of infrared spectroscopy (IR spectroscopy) in reflection mode, so that the ink film does not have to be removed from the substrate. Two signals are evaluated during the measurement: a signal that decreases proportionally by the curing process (measurement signal) and a signal that is not changed by the process (internal reference). The reference measurements are used to calculate the degree of curing of the submitted print samples. This method allows the printing inks and coatings used to be measured individually. The worst-curing ink system is used as a reference for determining the curing of multicolour print fields.

The results are summarised in a report.